OFFSET PRINTING

Contact Us

"*" indicates required fields

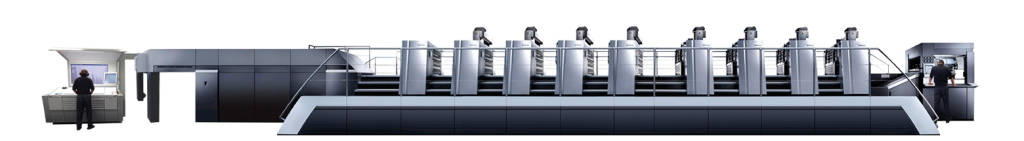

Featuring The Heidelberg Speedmaster XL-106

Offset Printing is still the preferred method for producing quality printed materials. Our pressmen are master craftsmen at running our state-of-the-art equipment and ensuring that the images they produce are pristine, registration is held and color is consistent.

As a result of our investment in Heidelberg presses and up to date color management technologies (Prinect Inpress Controls), color and brand consistency is guaranteed from job to job, and year to year. You’ll never need to worry about improper reproduction of your brand or corporate image.

With offset presses capable of handling projects from business cards to full color product catalogs, our one-stop solution addresses all your needs. Our line-up is unique and needs to be seen to be appreciated. We invite you to visit our Warner, NH facility at anytime where we can demonstrate how we achieve improved quality, often at prices lower than what you are currently paying.

Offset Printing with the Heidelberg Speedmaster XL-106

This incredible press gives us a distinct advantage over other commercial printers, by providing both quality assurances and more efficiency—to protect your brand while saving you money.

- We can print both sides of the sheet in a single pass, where as other printers can only print one, thus requiring twice as many passes and yielding 100% more production time.

- With our one of a kind Prinect Inpress Control technology, make ready times are up to four times faster than other conventional press configurations.

- In a direct comparison, 10,000 copies of a 32 page, 8 ½” x 11” full color publication, the Heidelberg XL106 will take 1/3 of the time to run versus its competitors.

Heidelberger Druckmaschinen AG manufactures a range of mechanical equipment products from its headquarters in Heidelberg, Germany. Heidelberg is one of the top makers of offset printing presses in the world and well-known for their superior quality and reliability. Nearly 47 percent of all presses of this type on the market are made by Heidelberg. These sheet-fed offset printing systems are ideal for producing a broad range of high quality color paper products including catalogs, calendars, posters and packaging labels. Heidelberg also manufactures various prepress, post press, press, and other equipment.

In Warner, we built an addition to our production space to house the first of its kind, in New Hampshire or Vermont, Heidelberg XL106 – Eight Color press with in-line coating that prints full color on both sides of a press sheet in a single pass. This premier catalog press handles a press sheet up to 29” x 41” and effectively helps to reduce the time to produce most catalogs and publications by half. This press is very unique with numerous technological advances that ensure your brand protection from project to project.

G7 Certified

R.C. Brayshaw & Company has achieved G7 certification for calibrating our proofing and press equipment to G7 standards set by IDEAlliance. Our G7 Certification was granted through implementing a calibration process that achieves a close visual match from proof-to-press.

R.C. Brayshaw & Company has achieved G7 certification for calibrating our proofing and press equipment to G7 standards set by IDEAlliance. Our G7 Certification was granted through implementing a calibration process that achieves a close visual match from proof-to-press.

We made the move to standardize to G7 so we can meet customer requests for a similar visual appearance between proofs and presses. Because G7 is device independent it doesn’t matter which of our presses are used. The G7 proof-to-print process is based on the principles of digital imaging, spectrophotometry, and computer-to-plate technologies. G7 is a precise calibration process that allows us to reliably achieve a visual match between proofing and printing methods.

Our adoption of G7 standards will improve communication between our customers and our staff and helps avoid disappointment in expectations. These improved processes maintain printing as a competitive force in the communications marketplace.

Prinect Inpress Control

Prinect Inpress Control is the inline color measurement system for the highest productivity and vivid color consistency on sheet fed presses available today. It automatically measures and controls color and register on the fly and at any press speed. Integrated directly into the press, the measuring unit measures process colors, spot colors and register in the print control strip. Any corrections required are forwarded directly to the Prinect Press Center for adjustment. As the press does not need to be stopped for either make-ready or monitoring of the production run, Prinect Inpress Control achieves maximum productivity.

Prinect Pressroom Manager

The Prinect integrated color workflow provides reliable inking and exacting color reproduction from job to job providing exacting and consistent color quality.

Inking up is quick and reliable with Prinect, and quality can be controlled and kept consistent across the entire run. How is this possible? In the integrated color workflow with Prinect, printing is based on well-defined, standardized values that can be reliably controlled with measuring equipment. At our prepress stage, for example, we establish parameters to automatically preset the press, thereby turning prepress and the pressroom into a single, closed loop system.

Offset Printing: Multiple Press Configurations

R.C. Brayshaw & Company has several offset printing presses in our arsenal- with our 41″ eight color Heidelberg down to our small format duplicators (and many sizes in between), we can always match the right equipment to the right job. Several of our presses can print in perfecting mode which allows printing both sides of the sheet in one pass. Our carton diameter presses can also print on extra heavy stock for your packaging needs. Being the best at ink-on-paper requires skill, discipline, and the right equipment, and we have the best in the business in our press room.

Perfecting

A perfecting press is a press that prints both sides of a sheet in one pass. As an example, a two-color press that can perfect may print black on both sides of the sheet, or it may print a PMS color on both sides of the sheet. It may also print different colors on the two sides of the press sheet. The key is that both sides are printed at once.

This process becomes particularly useful on a multi-unit presses, such as our eight-color Heidelberg Speedmaster XL-106. This press can print four process colors on each side of the sheet at the same time. An example of a good project for this press is a sixteen-page process-color booklet (eight pages on each side of the press sheet receiving four colors as the sheet passes through the press). The pressman prints both sides of the sheet in a single pass, completing the whole job in a fraction of the time required by a conventional press. This saves both time and money while achieving better color quality than presses requiring two passes.

Experienced Printing Craftsmen

Excellence in printing ultimately depends upon the ability to control ink on paper. Our expert pressroom personnel are masters of their craft – a combination of technical expertise and attention to detail. Today’s presses are highly automated, but the critical decisions about ink density, color balance, registration, and press speed are dependent upon a skilled operator. Simply equipping a press with a scanning spectrophotometer is not enough, only an expert pressman can still best utilize it for measured control throughout a print run. Talented and experienced craftsman, operating high quality equipment is the key to a superb finished piece. Having and choosing the BEST equipment for each type of printing is also of high importance.

R.C. Brayshaw & Company has several offset printing presses in our arsenal- from our 40″ format down to our small format duplicators, we can always match the right equipment to the job. And, we know when your piece is a perfect fit for our digital presses. Several of our presses can print in perfecting mode for printing both sides of the sheet in one pass. Our carton diameter presses can even print on extra heavy stock for your packaging needs. Being the best at ink-on-paper is hard work, and we have the best in the business in our press room.